How Do We Achieve High Accuracy?

Incoming Quality Control

We select suppliers of all raw materials based on our own reliable evaluation system to ensure stable & smooth production with high-quality incoming raw materials.

Each batch of incoming raw materials will be examined according to the AQL, CER & RoHS standards.

Sophisticated Machines

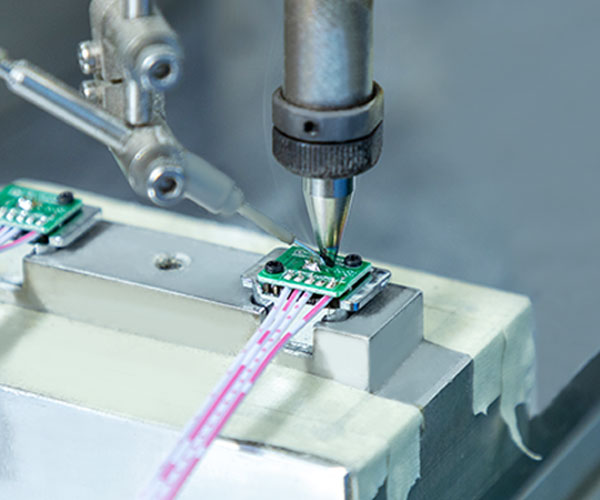

We developed our own machines to perform the tasks of assembling and packaging, based on a detailed and comprehensive study on the worker's moves.

With the help of such machines, we are able to reduce the mistakes occurring during the production process, which makes high accuracy guaranteed.

All Production Processes In-house

We are responsible for the whole process of producing a thermometer.

A full set of standard is executed through all departments and no problems will be ignored if it is occurring. Thanks to our in-house processes, we are able to trace and solve the problem right at the time other factories are trying to get in touch with their suppliers.

Specialized Workers

To ensure high accuracy, no detail shall be neglected, even it is just the worker's outfit.

Every worker who steps into the assembly workshop shall wear the anti-static wrist strap, hair mask and a shoe cover, allowing us to make sure that no malfunction originates from a worker’s inappropriate operation.

Eliminate Hazards by Pre-production

We will not start the mass production until the pre-production phase confirms that the subject type of thermometer is suitable for mass production.

Based on this, we aim at controlling and reducing the problems as much as possible from the very beginning.

Critical Components Producing & Controlling

Your designed shape of a thermometer is created by using the plastic injection molder. Using the ABS as the raw material and the customized mould, we make the enclosures with high precision.

With the help of the manipulators, one worker can successfully control two injection machines, allowing for the production efficiency to be greatly enhanced.

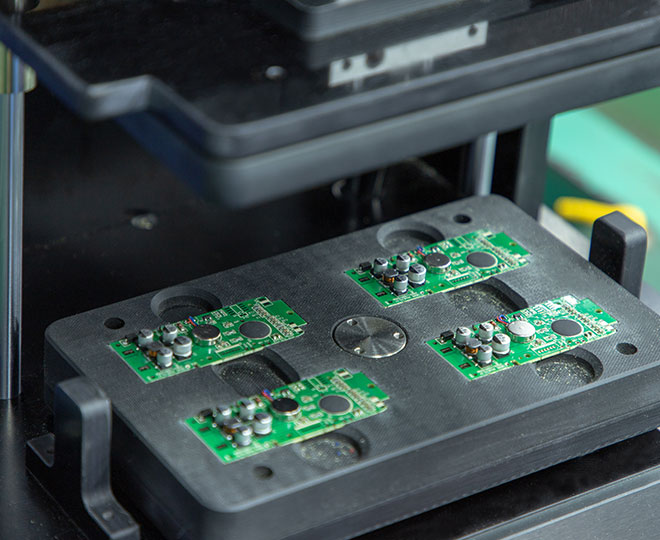

All PCBs used in our products are produced by ourselves. We have a specialized SMT workshop with Japanese high-precision machines.

PCBs sent for assembly must go through the microscope check first to ensure correct mounting.

Promised

Fast & Strict Assembly:

The Lead Time is Promised.

We design every part's assembling order with the aim of reducing any possible waste of time.

And with our self-developed machines in the assembly line, the 4 lines are able to produce 10,000 pieces of thermometers every day.

Still, we have never forgotten that quality outweighs speed as always. You receive only the batch of perfect temperature measuring devices that stand various tests.

- Semi-finished Testing

- Drop Testing

- Function Testing

Outgoing Quality Control

Temperature Test >>

Using water tank to test every piece of thermometer, making sure they are functioning perfectly.

Keystroke Life Test >>

The keystrokes will be tested to ensure a longer life.

Simulation Vibration Test >>

Preventing any harm caused by vibration during transportation.

Environment Adaptability Test >>

Simulating environments by presetting temperature and humidity to avoid malfunctioning in your target market.

Package & Storage

Package

We ensure a correct package with stickers, labels, specs and the package boxes. You can contact us for package customization.

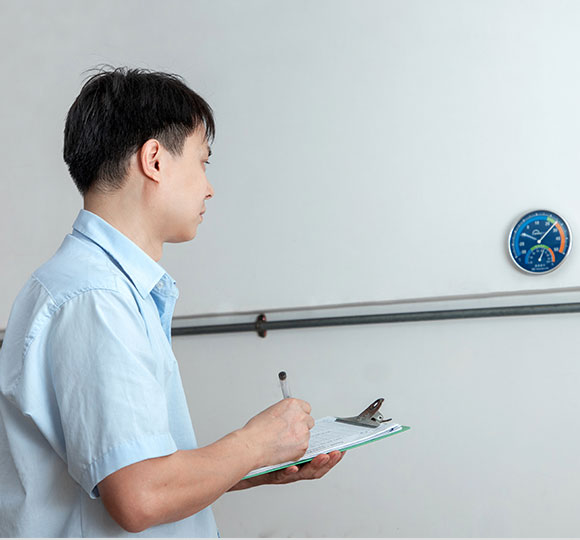

Storage

All finished goods are stored in the electronic warehouse with constant temperature and humidity. Our warehousing expertise make 2 inspection tours every day to make sure the products will not be harmed by improperly set temperature and humidity.